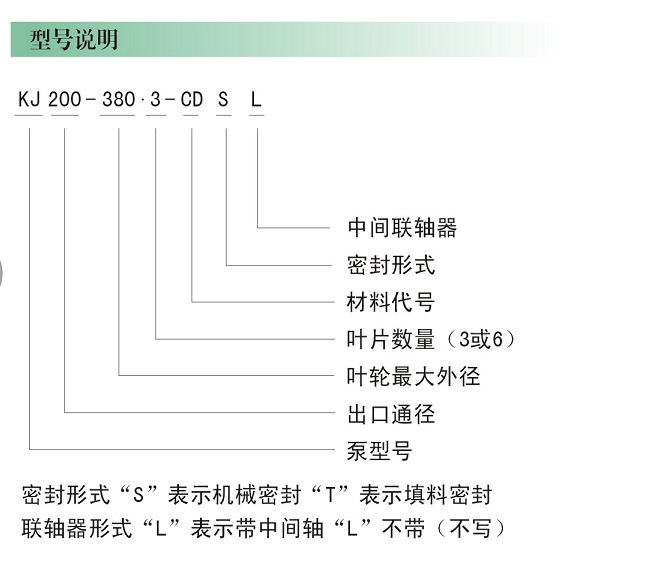

KJ pulp pump

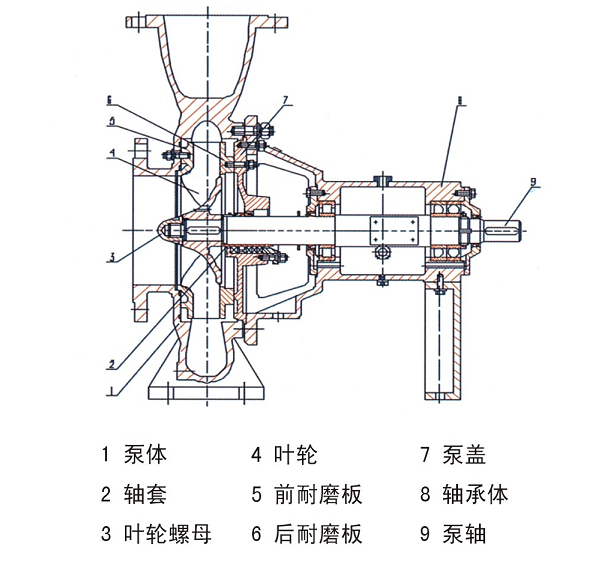

Referring to foreign advanced technology, self-developed single-stage single-suction cantilever centrifugal pulp pump, 3-6 pieces of fully open impeller, economic operation, strong medium through capacity, can transport the concentration of up to 6% below, containing a certain amount of air slurry and similar materials, before and after the wear-resistant plate clearance adjustable, stable flow head. The same condition single machine operation cost is low.

Product features:

1. Fully open wide runner impeller, not easy to plug, higher slurry concentration; The axial force is small, the whole machine has no vibration, the weight of the impeller is lighter than the closed and semi-open impeller, the radial shear stress of the shaft is small when starting, the service life of each part is long, and the relative maintenance rate is low.

2. The impeller, rear wear plate, shaft seal component and bearing frame can be used as a "push and pull component" to disassemble and install without disassembling the pump inlet and outlet pipeline with the intermediate coupling.

3. Thickening the pump body where it is easy to wear; The impeller blade and the rear wear-resistant lining are thickened, which greatly improves the service life.

4. Effectively reduce the pressure at the shaft seal to reduce leakage.

5. The main parts are precision cast with wax loss, the inner wall of the product is smooth, and the impeller is G6.3 dynamic balance check.

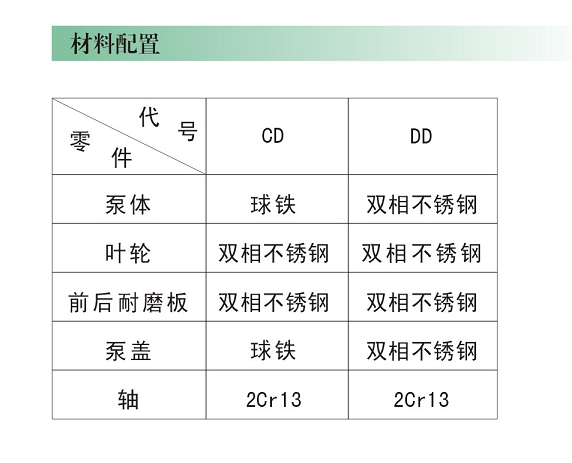

6. There are a variety of sealing methods and materials for users to choose.